<< New Q&A

More Q&A, part 9 >> Part 8

>> Part 7 >> Part 6 >> Part 5 >>

Part 4 >> Part 3 >>

Part 2 >> Part 1

>> Gunwriters guns.connect.fi Link page

Custom Search

Latest update 30.01.2001

G.O.W. Kickback:

Questions and Answers, Part 10

Answered by: P. T. Kekkonen

444 Marlin

for T/C pistol

444 Marlin

for T/C pistol

Hello; I have just stumbled on your website and it is the best I have seen in a long time.

We have now similar problems with hoplophobes.

How does Finnish laws treat Thompson Contenders? I have an original TC 12" barrel, 44

Rem Mag, that was rechambered for 444 Marlin. Being scared, I have only loaded up to 1700

fps with 265 gr. Hornady FP (3031). TC does not even want to talk to me, but JD Jones

reckons, I can shoot factory ammo from this thing. Any ideas?

Kind regards, Eugene from South Africa

In Finland is

T/C Contender "a handgun for target practise only". Usually acquired for

Metallic Silhouette shooting. Not (yet) allowed for hunting, but use of it is legal for

shooting of a "Coup de gráce", i.e. put-down shot to any and all

species of wounded game animals. Even the biggest species like moose or bear. Use of

handgun is also allowed for shooting of trapped animals or those pursued into den or lair.

Trapped animals are usually small-game species like minks or foxes. Most usual

"trapper's gun" is a revolver or selfloader pistol caliber .22 Long Rifle. Usual

"Coup de gráce" handgun for big game is a 9 mm Luger caliber selfloader pistol

(many times an original Parabellum P-08 or Mauser C-96/16), although our Game Act allows

use of even the .25 ACP waistcoat-pocket handgun for this very purpose. There is not any

minimum muzzle energy or a bullet weight & construction demand for this very use on

our Game Act.

Some T/C Contender pistols with longest available 14" barrels, caliber .30-30 WCF,

rechambered to shoot .308 Winchester cartridges and equipped with a non-detachable

buttstock were made in Finland in early 1980s for moose hunting, until arrival of

amendment of Firearms Act, giving to us the minimum barrel lengths and overall lengths of

shoulder arms. In 1998 the demand of minimum barrel length was shortened somewhat, to 400

millimeters, and gunsmiths were learned to extend the barrel lengths by mounting of muzzle

brake/ recoil compensator or, since 1993, by mounting of an integral suppressor to extend

the barrel up to the legal dimensions. Use of a suppressor has been legal, even on the

hunting firearms, since 1st August 1993.

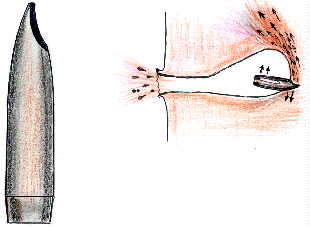

GOW archive photo: This T/C Contender chambered for 45-70 Government

did not like full power+ loaded heavy bullet ammo. This lucky snapshot shows the pistol

breaking off it's front grip by recoil. One-of-a-lifetime photographer's occasion.

J.D. JONES is definitely a TOP authority on T/C Contender! If he says "yes" it

means: YES! All the listed handloads of .444 Marlin generates less than 40 000 CUPs

chamber pressure, while some .308 Winchester factory-loads may generate 55 000+ CUPs.

According to the S.A.A.M.I. standards were maximum allowed average chamber pressures (20

years ago) 55 200 CUPs for .308 Winchester factory-loads and mere 47 200 CUPs for

factory-loaded .444 Marlin cartridges.

I have shot at least a hundred rounds of .308 Winchester factory-loaded cartridges from a

T/C C carbine, buttstocked from a .30-30 WCF caliber (rechambered) T/C Contender pistol. I

have still a hairy head on my shoulder, two intact blue eyes (slowly blindig by the Diabetes

Mellitus, however) on my face, and all five full-length fingers on my both hands.

1601 MMI; PT

Fyell-deer loads for an "Elephant Gun"

Pete Kekkonen, I found your great web site today. I'm hunting a deer (small European deer)

in close proximities to houses on a special hut, organized by the community. I have been

using a reduced load in my .340 WM at about 700 m/s with a 225 gr Hornady SP propelled by

52,5 grains of N 135. This loads performs well and is reasonably accurate (1,5 MOA).

However, it is still too loud! I'm in the situation where I can try even more reduced

loads like 15 - 18 grains of N310 (+ dacron) behind a cast bullet weighing 235 grain. Or I

can get a supressed Ruger bolt action in .44 Magnum rifle at a reasonable deal.

My questions are: Am I in the ballpark with the N 310 load in the .340 and is it safe?

Should I forget the .340 for reduced loads due to the huge capacity and just get the .44

Mag.? I expect the .44 Mag to be more effective at low velocities. I can get cast bullets

for the .44 Mag. weighing from 180 grain to 400 grain. For a subsonic hunting load - what

will be the best bullet weight to go, and with what powder charge?

Yours sincerely, Vegard from Norway

"All

those f**king Weatherby calibers are risky calibers for reloaders", according to many

ballisticians, while: "Behaviour of a 20 x 138 mm Solothurn Long cartridge is easily

predictable". However, use of a cast bullet may be the way to useful low-noise load

for hunting of Norwegian fyell-deer/ fell deer, along with ALL known special tricks, like

dacron-filling & use of the most efficient available Magnum primers, Federal N:o 215,

and drilling of the priming-flash hole to diameter 3½ millimeters. Your estimated charge

15 to 18 grains of VihtaVuori N310 powder seems to be O.K. behind 235-grainer CAST bullet.

Try first 18 grains charge and reduce it (if needed) down to 15 grains. Always shoot at

least five rounds of cartridges to the target with each load lot and adopt the charge

which generated least dispersion (= smallest group = best accuracy).

I presume that you don't need to acquire a .44 Magnum rifle, because the smallest

applicable loads of .340 Weatherby Magnum are not noisy, if you use those lead alloy

bullets ONLY!! 15 grains of N310 is not yet the definitely minimum charge. So you may get

a subsonic bullet velocity and accordingly reduced noise of shooting. I cannot recall,

whether use of the suppressor is banned or allowed in Norway, like it is allowed in Sweden

and Finland. With a suppressor mounted and cartridges loaded to give subsonic velocity

level, the very most noisy "shooting signature" is a smack of a bullet, striking

on the side of a fyell-deer.

A little bit of Zoology

These animals exists also in North-East Finland: Petra or peura (Rangifer Tarandus

variatio Fennica). Once upon a time they were slain to almost exhaustion with crossbows

and muzzle-loader rifles, shooting spherical lead bullets, calibers from 7 mm to 10 mm.

Last specimen of original Finnish wood-petra population was shot in 1921. But there was a

strong population of wood deers also in Russia. During recent decades those deers were

immigrated to Finland. Nowadays we have so dense population of Finnish deers that limited

hunting of them is possible. Domestic raindeer is actually a tamed Norwegian fyell-deer

(Rangifer Tarandus), bred to grow bigger than wild deers. In Finland are found also

cross-breeds of raindeers and Finnish deers.

In South-West Finland lives a very dense population of whitetail deers, brought in 1930s

from Minnesota, USA, reproduced from 32 imported animals. Whitetails and Rangifer deers

are unable to become cross-bred, as far as I know. Name "Petra" was a trademark

of Finnish selfloader hunting rifle, made by Valmet Oy and later by Sako Oy; nowadays

discontinued. (In USA the trademark was vulgar "Valmet Hunter"). I was a

"godfather" of this very rifle model, proposing the archaic/ original name of

Finnish deer for it. In modern Finnish is the common name for all kinds of deer, including

the foreign whitetail, simply a "peura". Reindeer is, however, a

"poro" in Finnish.

1701 MMI; PT

Selector/safety of KP/-31

I need the scheme of firing selector of Suomi Submachine Gun

KP/-31. Can you send it to me?

Carlos from Spain.

Si, we can!

Selector/safety is a sliding L-shaped piece of steel ahead of a trigger. Positions of it

are:

SAFE = rearmost position. A slide inside the trigger mechanism prevents

movement of the trigger and sear. It is impossible to cock the breech-block or discharge

the gun, when safety is applied. (Fig. a)

SEMI-AUTOMATIC FIRE = mid-position. The selector slide allows movement of

sear and trigger, but it disconnects trigger from the sear soon after the breech-bolt

starts it's movement forwards. The sear can move upwards to catch returning bolt. When the

trigger is released, it is again connected to the sear for next shot. (Fig. b)

FULL-AUTOMATIC FIRE = frontmost position. Selector slide cannot reach the

disconnector, which pull the sear downwards. Shooting continues until the trigger is

released or magazine of the gun is empty. (Fig. e and f)

0201 MMI; PT

Reduced loads for a buffalo gun

Just a note from a Texas shooter that appreciates the information on light loads or

reduced loads. I have been playing around with some light loads for my little .458 Win

Magnum. Since the huntable elephant population in Texas is 0 at this time, I thought it

appropriate to create some lighter 45-70 type loads for wild hog, Russian boar, and deer.

Using 300 gr JHP or 405 gr lead bullets and 2400 powder I now have loads appropriate for

medium game. I was not happy however. I wanted one gun that I could use on everything. I

now have a couple of loads that use either a .458 round ball or an old style collar button

bullet, in conjunction with "Bullseye" powder. I now am in the process of

testing and the preliminary results are encouraging.

These loads are chronographing around 275 to 300 m/s, and should be ideal for rabbit and

other small game.?Imagine, one gun that takes everything from squirrel and rabbit to

elephant and cape buffalo. It makes you want to kneel down and say, Thank You Jesus, and

God Bless Texas! Anyway I am going to fine tune these loads and will send you the

specifications for the light loads. You have a great site with fantastic information,

after I saw you had some good things to say about one of my heros (Larry Thorne) I knew

for sure you were not some Commie Bastard hiding out in Finland.

Best wishes for the New Year,

Kevin, Dallas, Texas

Comments of

Chief Editor: Your experiences about versatility of .458 Win. Magnum are

welcome to our website. One of my friends in Finnish Lappland loaded also his .458 WiMa

cartridges with wide variety of reduced charges, starting his experimental work almost 20

years ago. Powder used was VihtaVuori N320, with burning rate somewhat slower than that of

"Bullseye". So my friend reduced volume of the case with?pieces of soft Mipolam

(PVC plastic) hose, squeezed into lubricated and somewhat heated cases. Diameter of these

"case liners" was 12 millimeters (outer dia.) and 9 mm (inner dia). Length of

liners was about 50 millimeters. Usual bullets were Sierra Jacketed Softpoints or

Hollowpoints, with weight 300 grains.

For big-game hunting these bullets are miserable projectiles if their striking velocity is

too high, but at "soopoo" (subsonic) velocity the 300-grainer Sierra JSP or JHP

is OK even for hunting of moose or Finnish bear (Ursus Arctos). Correct placement of hit

is, of course, essential and the distance of shooting should be short. My friend had a

team of dogs harnessed to the sleigh. It is illegal to shoot game animals from?motor

vehicles like "Ski-Doo", but hunting from a dog-sleigh is allowed in Finlad.

Shooting distance was usually less than ten yards.

"Imperial" dimensions of liners are: Outer diameter .47, inside diameter .35 and

length 2 inches, approximately. When you load lined cartridges, you may/should reduce the

powder charge according to the reduced case volume. PVC (hose) liner shall last as long as

the case itself, and it allows depriming with usual equipment. We don't know, how

long-lasting may be the India Rubber hose (of red natural rubber). Big bullet does not

make the rifle unfit for hunting of small-game animals like hares, rabbits or squirrels.

Your .458 WiMa is OK for purpose.

My 12.17 x 44R Swedish Remington rifle may be also a good squirrel rifle, when loaded with

.500" diameter spherical cast lead-alloy bullet, but I have not a legal right to

shoot this ancient wall-hanger, made by Carl Gustav Stads Gevarsfaktori, Eskilstuna,

Sweden, in 1875. I have not cartridges or even the cases for my "Svensky

Remington", although the new high-quality cases for it are available from Australia.

In Sweden was 12.17 mm rifle a popular instrument for hunting (or poaching) of all kinds

of game animals, big or small, usually with the spherical lead bullets and blackpowder

handloads about a century ago, but presumably still later. Factory-loaded cartridges have

been unavailable since 1st World War; I presume.

Remington rifle was also a good appliance for fishing of the pikes, spawning on the

flooded area at riverside meadows. Swedish television (Svenska Radio) produced in 1970s a

document "Remington-Olle" about an old poacher & fisher, who shot the pikes

with his old Remington, using black powder and spherical cast bullets. This kind of

fishing was, of course, illegal in Sweden, but the story was produced by an exceptional

allowance - to show "fishing methods of by-gone days" - and the versatility of

ancient Remington rifle. I presume that .458 WiMa rifle may be also a fine fishing

appliance, but use of it may be illegal for this purpose in Texas too.

0501 MMI; PT

Send my for question load sub-sonic:

Lapua case .308 Winchester. Lapua B-416 sub-sonic is possible change D-46 185 gr? Primer

CCI BR-2 Large Rifle or Magnum primer? Charge 10.6 grains of N310 or N320? O.A.L. 2.620

Best Regards: Roberto from Italy

185 grs Lapua

D-46 is preferable. B-416 is unstable when shot from a bore with more than 240 mm twist of

rifling. This bullet was actually designed for 7.62 x 39 mm and 7.62 x 53R cartridges.

CCI BR-2 primer is sufficient if the primer pocket's flash hole ("vent") of case

is enlargened to 3.5 mm diameter. Charge 10.6 grains is correct with both of these

VihtaVuori powders, owing same chemical composition, but different size and shape of

kernels: N310 is a "stick powder" with very thin solid kernels, while N320 has

more large tubular kernels.

Sensitivity of ignition is similar: Powders are very flammable, because of their rough

kernel surfaces. Burning rate of N320 is slightly slower than rate of N310, but this

difference is too small to cause nasty surprises unless the charge is considerably below a

safe minimum. 10.6 grains of powder, either N310 or N320 is not definitely a minimum load,

but a starting load for search of a good subsonic charge. You may lessen it, or add

slightly more powder if needed. Lower limit is ca. 9.5 grains and maximum charge ca. 12

grains. Lubrication of bullets is always beneficial way to keep the bore condition/ bullet

velocities uniform.

2812 MM; PT

Long Tom

Grandpa Bert is wondering where the term "Long Tom" comes from? We are aware of

an old 12 gauge shotgun that the owner refers to as a Long Tom shotgun.

dg.

This pet name

of Pennsylvanian-Kentuckian long-barreled rifle or shotgun is presumably born during

flintlock era. Some gunsmith owing first name or family name Thomas had built a bore drill

and rifling bench for making of extra-long squirrel rifle barrels? (In 1700s and early

1800s should gunsmiths usually made their own "machinery" first). "Long

Tom" barrels could be as long as 60 inches. In the mid-1970s offered Dixie Gun

Works, Inc. on their catalog No. 124A drilled and reamed octagonal barrel blanks,

presumably made in Spain, size across the flats 13/16 inch. Caliber was .43 and length

full five feet. This smoothbore "Dixie Five Foot Long Tom Rifle Barrel" blank

was available at $ 19.95 without thread for a breech plug.

Rifles with 1.52 meter long barrels were not very handy in the woodsland. They were also

difficult to load and clean the bore. Long Tom rifles never became popular, because their

accuracy and range were not enhanced. In Finland this name is unknown, but we have an

exclusive kind of handmade sheathed knife "TOMMI puukko" still in

production by knifesmith family Kemppainen or Keranen in Kainuu region,

Finland. Name "Tommi" derives from a British foreman Thomas

Woodward who moved from Sheffield, England in 1862 to Finnish Fiskars

manufacture to learn hardening technology of then-new Bessemer and puddled carbon

steels. In 1875 he became a manager of Hackmann's Nurmi factory.

Woodward died in 1878. He was taught technology of hardening and tempering by

oil-quenching to many workers of Fiskars and Hackmann factories. One of them, Kalle

Keranen, returned to Kainuu region, starting puukkosmithing. "Official

name" of this very puukko desing is "puukko of Kainuu", but "Tommi-puukko"

is well-known pet name of these knives with very keen and hard high-carbon steel edge.

Tommy Woodward didn't design this traditional knife, but he taught to knifesmiths of

Kainuu a successful hardening & tempering method for knife edges.

Designer of Long Tom rifles and shotguns is unfortunately unknown to me, but there was

probably some person behind a name.

1612 MM; PT

Berthier and Chatellerault

I have two rifles that my father brought home from France after WW II and I am trying to

find some general information on them. I read one of your responses about the Berthier

Rifle on your question and answer page and thought that you might be able to help me out.

I have a carbine that is a Berthier Model 1892, Artillery Musketoon (Mousquetons d'

Artillerie). Manufactured by Manufacure d' Armes Saint Etienne sometimes

between 1892 and 1916. I was told that a Mle. 92 is somewhat rare and not a common find.

The other rifle is a long rifle that is also chambered for the 8 x 50R Lebel cartridge. It

has the serial number 85026 stamped all over it. It has the words Chatellerault

MLE 1907 15 and came with a MLE 15 Epee Bayonet. I am told by an expert "This is most

likely a Berthier Model also as Chatellerault did not make Model 1907 Rifles." If

this is true why is Chatellerault inscribed on the barrel?

Thank you for any information that you might have. I am trying to document as much

information as possible on my collection of guns to leave for future generations.

Greg from Iowa.

There was not

any "Manufacture d'Armes Berthier" in France. Berthier was just a

designer of clip-fed rifles and carbines. State-owned manufactures/arsenals assembled

them. During the First World War (the BIG ONE) was not uncommon that some manufacture

assembled some models of firearms but the parts (including barrels) were made by another

arsenal, owing more production capacity of these parts. Example given: Chatellerault

might have extra capacity for drilling & rifling of the barrels, while St. Etienne

had insufficient capacity to produce them. So St. Etienne bought barrels from

Chatellerault. Because barrel is an essential part of a rifle, it was necessary that name

of it's manufacturer is inscribed on it. In France was even the name (code) of cartridge

case manufacture and sometimes source of brass material headstamped on the cases, which

were primed, loaded and bulleted elsewhere.

This subcontractor method was also usual in Imperial Russia during 1st World War: Finnish Tikkakosken Rauta- ja Puuteollisuus Oy made breech-bolts

and cast brass or bronze feeder frames for Russian Maxim machine guns. In independent

Finland made a sporting rifle shop of gunsmith Joonas Matarainen (later Mikro

Oy) barrels for Suomi KP/-31 submachine guns. There were at least two barrels issued

for each KP/-31 and usually at least one barrel for shooting with blank cartridges.

Tikkakoski Oy had not enough production capacity to drill and ream all the barrels &

cut the rifling grooves and lap the bores just like bores of high-quality target rifles

were lapped in Finland.

Subcontractor Mikro Oy's KP/-31 barrels was urgently needed especially during the Third

Finnish Independence War 1941 - 44, when the submachine guns were mass-produced also for

export.

1212 MM; PT

Please: Don't cease!

Hello! I stumbled on your site while searching for the subject of reduction of muzzle

velocity, and find it a most excellent resource. I hope you are able to continue and gain

patrons. I would be willing to put up the $US 20 if only for the information already

gained against the prospect of picking bits of a chamber out of my face with tweezers

because of S.E.E.

I have not searched your site exhaustively with an eye for current developments,

concentrating more on the wealth of loading information, and I am wondering if you have

any better idea now what your prospects are regarding the future of your site.

I do have some specific questions, and will continue to do research of course, and not

presume on your hospitality without having "done my part" for your site. I find

it unfortunate that people have developed the attitude that the freedom of this wonderful

medium of information dissemination implies freedom from cost. It seems there is much

excellent knowledge available from your country, and it would be shameful for it to be

lost to the rest of us because of that attitude.Killing the goose that laid the golden

egg, indeed! Many thanks if it is within your ability to respond!

Th. A M

and comment:

Welcome to The Club! Privileged visitors of GOW/ Universal are always privileged to enjoy

our service! Your fingers and eyes are presumably a lot more valuable than a printed

picture of the late U.S. President Andrew Jackson. I've not met any printed

Handloading Manual containing data for SWOS loads, "Cat's

Sneezes" or other information we have offered. And especially in Finland it is an

opinion that "this data for the terrorists and poachers shall never become published

on the printed manuals". GOW shall therefore possess still a monopoly as a

distributor of scientifically researched data on the subsonic handloads of rifle

cartridges.

1212 MM; PT

Bergmann MP article in English too?!

I was happy to find the Gunwriters Suomi site. It covers more

information than I have found anywhere on the model 31 or 44. I cannot seem to translate

the site for the MP-18 though, and was hoping there was a site in

English, or would be soon. Do you have anymore sites that are that informative, in

English, for any other weapons?

Thank You. M.E.

Sorry; I have

no time to translate articles as large as the Bergmann MP story into English. There are no

more than 24 hours in a day & night. Our Finnish visitors are up-keeping our site.

They are therefore always privileged to get information.

1712 MM; PT

Hydrodynamic .22 rimfire bullets

Hi PT, In an earlier post you mentioned making "exploding" .22 rimfire bullets

by filling the hollowpoint with common vaseline. Does the hollow need to be enlarged for

this to work? In the states we have achieved similar results by filing the tip of the

bullet flat. Thanks very much.

Dave

Enlargement of hollowpoint is unnecessary but deepening of it is beneficial, if not

essential. In 1980s had just Lapua .22 LR HP bullets deep enough point cavity, with

diameter no more than 1/10" or one Russian "linya", but with

average depth seven millimeters, up to .28 inch. Ancient Record injection syringe with 2

cc capacity was an ideal instrument for vaseline/ "mineral jelly" filling to

narrow point cavities of these bullets of my pet Lapua "Sound Moderator HP"

cartridges. It was possible to warm-up the glass & metal syringe with a candle flame

so that the vaseline ran easily through a shortened 20 Gauge intramuscular vaccination

needle (diameter 0.9 mm/.0355 inch, with a nominal inside dia. 0.584 mm/ .023 inch).

Needle was shortened to the length ca. .28 inch and the syringe was filled with molten

liquid vaseline. It took 2 to 3 minutes time to fill point cavities of fifty .22 LR Lapua

S.M.H.P. bullets with this miniscule "grease gun". Today it takes a lot more

time, because Nammo-Lapua Oy H.P. bullet point cavities are considerably less deep than

.27+ inch. I don't know: why? Old SMHP .22 LR cartridge was at least as accurate as the

famous Eley Tenex in most rifles I've tested, including Remington Nylon 66, in my

possession since late 1970s until mid-80s.

Remington didn't accomplish automatic feeding cycle, when loaded with Lapua .22 LR SMHPs,

but a manual feed took less time than loading of my single-shot TOZ Model 8 rifle (with an

integral suppressor or a real silencer) and it was usually loaded with 14 + 1 cartridges.

Once upon a time I shot three crows at a tree-top from a MEASURED distance 175 yards (160

meters). There were three eye & ear witnesses of occurrence at the place. I had a

self-designed self-made suppressor mounted on the muzzle of Remington rifle.

Witnesses standing ca. 100 yards aside were unable to hear any shooting signature from my

firing post, but a loud "smack" when a vaseline filled hydrodynamic bullet hit a

crow, sitting on the high spruce top. Another crow came soon on the same tree-top. It was

a regular post of "sentry crows" close to a fur-bearing animal farm. The farmer

was called us to "make thinner" the crow population, robbing the fodder issued

to minks and foxes breeded on that farm. Once again a suppressed "Tlick!" from

my Remington and a dull "Smack!" from a tree-top. Another unfortunate sentry

crow rolled down from the spruce-top. Third one came to the sentry post a couple of

minutes later. Again: "Tlick!" and: "Smack!" Third crow was able to

glide away. We didn't find it from a forest surrounding the farm.

The kills, two crows, were photographed (when I was cut away about a yard of bowel,

hanging from the stomach of a crow, hit by my second shot), and the

"self-censored" photo was published on the Finnish "ERÄ" magazine.

One of the eye/ear witnesses of my personal "long-range shooting record" was a

professional photographer Matti Mäkijärvi, who was my partner until the end of my career

as a technical/ ballistician contributor of the "Erä" magazine. Matti recalls

still that he was unable to hear nothing but those three "smacks" of

hydrodynamic .22 LR SMHP bullets from the spruce-top.

Today it is needed to drill the bullet cavity with a drill bit with a diameter .10 inch or

2.5 millimeter to depth .27 to .28 inch. Fill the cavities with hot liquid vaseline,

because modern disposable plastic injection syrinces of poly-propylene or polymer 66

(Nylon) are unable to endure heat of a candle flame. Syringes with 2 CC or 3 CC are

preferable for vaseline filling of bullet cavities. 5 CC syringe is too large for this

very purpose. If 13 or 14 Gauge needles are available, they are preferable, because of

their large inner diameter .063 or .070 inch. A "Luer" hub of needle is

fit for disposable syringes. ("Record" hubs are presumably obsolete).

Cut the needle to length somewhat less than .30 inch. I'm using disposable B.D. insulin

syringes with their thin ½ inch long 29 Gauge needles, but I use metallic mercury as a

bullet cavity filler if needed. Mercury-filled bullet of a .32 ACP Browning/ FN Model 1900

pistol had a remarkable role in Finnish history: A Russian Governor General and a Dictator

over Finland, Nikolay Ivanovich Bobrikov, was wounded by the very most lethal

projectile of .32 ACP in 16th June 1904. This bullet hit his belt buckle, but the mercury

filling of it, along with the fragments of lead & mercury amalgam, and shrapnels of

bullet point cover, an "amalgam powder" (mixture of silver, gold, copper and

tin, bought from some dentist) were able to produce more than 140 tiny perforations to the

small intestine of a Dictator Over Finland. Neither explosive shell nor "DumDum"

bullet of .32 ACP is able to cause such injury.

In 1904 the peritonitis was a definitely lethal

sickness. Old dictator deceased in 17th June, about 3:00 a.m. His last words were: "Pochemoo?

Pochemoo?!" ("Why? Why?!" in Russian ). I hope that millions or a

billion hoplophobes on the world shall ask this same question, everywhere on the Globe,

before their slow and very VERY painful death!

In 1904 the peritonitis was a definitely lethal

sickness. Old dictator deceased in 17th June, about 3:00 a.m. His last words were: "Pochemoo?

Pochemoo?!" ("Why? Why?!" in Russian ). I hope that millions or a

billion hoplophobes on the world shall ask this same question, everywhere on the Globe,

before their slow and very VERY painful death!

Governor General Nikolay Bobrikov brought the gun control to Finland

already in 1903.

Metallic mercury may be hard to acquire in "People's Republic of California",

but the copper paste, available from gas stations or garages is some

"between/betwixt" material according to some Finnish gunwriters (privileged to

get their articles published in the printed periodicals). I don't know their method, how

to inject the copper paste into a deepened bullet's point cavity. "Meplatting"

of bullet tip, i.e. filing it flat is O.K. for the short-range jobs, but it shall

deteriorate Ballistic Coefficient of the bullet, making it's

trajectory more crooked.

Old tricks are also splitting of bullet tip with a knife or slashing a cross-shaped

incision on the tip of bullet's point. These incisions, one or two, should not necessarily

be very deep, but just scratches; depth one millimeter or so. They'll enhance expansion of

bullet's point. More recent innovation is "Loeffelspitzung" of bullet

tip. (German: "Loeffel" = spoon or small dipper; "Spitz"

= point or tip). It may be done by carving or simply by pressing a shallow

"dimple" on the side of bullet tip. Loeffelspitzed bullets are usually as

accurate as intact projectiles in flight, but they shall tumble after the hit, being

asymmetric.

Trajectory of spoonpointed bullet is somewhat more crooked than trajectory of intact

projectile. If the spoonpointing is uniform (width and depth of each pit or dimple are

similar on each bullet) trajectory of every bullet is also similar. Sight may be

re-adjusted for shooting with spoonpointed bullets. These projectiles shall loose their

flight stability and tumble over in flight, but the range is usually about a thousand

yards. (Depends on twist of rifling and width/depth of a dimple). Air resistance shall

slow down the rotational rate of spoonpointed bullet until it is too slow for

gyro-stabilization. Shortened hazardous range is beneficial from viewpoint of shooting

safety.

Point of solid brass 4.7 mm spoonpoint bullet. Considerably less

asymmetricity shall be efficient if the bullet is a long pointed boat-tail projectile,

just marginally gyro-stabilized in it's flight, but stable within all practical ranges of

actual shooting.

Loeffelspitzung was designed for military purposes; almost adopted in West-Germany for 4.7

mm solid brass bullets of their Heckler & Koch assault rifle. In 1970s vetoed

International Committee of Red Cross, because Loeffelspitz bullets inflicted "at

least as horrible wounds as explosive or Dum-Dum projectiles". Germans ceased

development of 4.7 mm assault rifle and spoonpointed bullets. Russians designed about in

the same time their 5.45 x 40 mm cartridge and bullet with terminal effect similar to

German Loeffelspitz bullet, but they managed to hide "intrinsic asymmetricity"

into the intact steel jacket.

Pointed FMJ rifle bullets are improved in Finland by filing the tip very sharp from one

side, just like a tip of ancient quill or an usual hypodermic needle. Asymmetricity is

usually less than one millimeter, but terminal effect of a long (marginally

gyro-stabilized) bullet is "impressive". Some moose hunters and many poachers

know this trick in our country. Filing of bullet tip is done so carefully that the lead

core shall not become exposed. It is also possible to "emboss" a dimple on the

ogive of bullet's point, about four or five millimeters rearwards from the tip, with some

thin ball-pointed tool or to drill a tiny hole through jacket on the bullet's ogive.

Usual diameter of a drill bit is 2.0 millimeters and depth of the hole is to central

longitudial axis of the bullet. Use of full-metal jacketed bullet for moose hunting is

illegal in Finland, but drilled projectile is allowed for purpose, because lead core is

visible on it's point. Poachers use "quill filed" bullets or those with a dimple

embossed on the ogive. Most poachers are, however, using common factory-made cartridges or

handloading components, but: "Kaikkea on kokeiltava, paitsi kansantanhuja ja

pikkusiskoa" says a Finnish proverb. (= One should try everything, with

exceptions: Country-dance and little sister).

1112 MM; PT

Suppressors & subsonic loads for .308

Winchester

In your publication you state that a rifle with a 1 in 12"

twist rate should not to be used to fire ammunition with bullet weights greater than 150

grains due to stability problems - this being especially true when using such ammunition

with suppressors, where an unstable bullet might strike the baffles damaging the

suppressor and/or injuring the shooter.

Unfortunately the only commercially available subsonic ammunition in this caliber (made by

Lapua or SM Thun) is available with 200 grains bullets here in

Switzerland. Some quick mental calculation, assuming a 220 000 RpM revolutions for the

bullet, and a distance of 140 mm from muzzle to the end-cap seems to indicate that a

bullet would have completed about one revolution. So: While a 200 grains bullet is

probably not stable in this twist rate at extended range, it is likely to suffer from

serious stability problems inside the suppressor?

It is hard to understand that a single revolution outside the rifle's bore is enough to

stabilize or de-stabilize a bullet. The suppressor I'm looking has a 9 mm passage through

the baffle stack and a 10 mm end-cap passage, if that helps in your calculations. On your

relatad note you state that full-power ammunition should not be fired through suppressors.

But why?

I note that it is common practice to do so in the .223 Remington caliber - in fact: A

reputable manufacturer of suppressors in Switzerland sells suppressors for use with

assault rifles firing full-power ammunition. I realize you won't suppress the supersonic

crack this way, but you should still be able to suppress the muzzle blast without damaging

the suppressor - or not?

Yours sincerely; Rory (Switzerland).

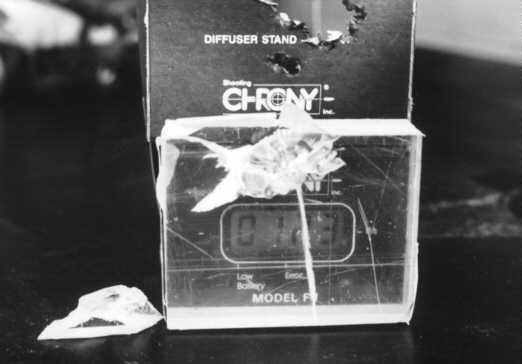

We almost lost a Chrony chronograph during sonic barrier tests in 1992, when we shot 200-grainer Lapua

bullets from a .308 Winchester rifle with 1 in 12" rifling twist. Fortunately enough,

there was a 150 x 150 x 150 mm acrylic plastic cube as a shield in front of electronics of

the chronograph, and the bullet hit on the shield sideways. Some bullets couldn't hit the

chart, size 1 x 1 meter at 50 meters distance. They were TOTALLY (not probably) unstable.

Bullet was actually designed for 7.62 x 39 mm assault rifle with a 240 mm rifling twist.

In .308 Winchester rifles with 1 in 10" twist these bullets were just marginally

stable; accurate in summer but unstable in frosty winter days, when the factory-loaded

.308 Win. cartridges were usually no more "subsonics" but just

"trans-sonics" with audible sonic crack.

"Blagodaryu Gospodinam!" (= "thank God!" in Russian) Lapua Oy

has ceased production of these bullets and "subsonic" .308 Win. cartridges

loaded with them. Frankly speaking: Production of factory-loaded subsonic cartridges for

rifles with variable rifling twists like those for .308 Win. rifles, is a sheer madness,

unless the nominal (test-barrel) muzzle velocity is ca. 290 meters per second and the

maximum bullet length is no more than 3 times diameter = 23.5 millimeters for .308

bullets.

German Finower Industrie GmbH, in Finow/ Mark was able to load very successful

subsonic 7.9 x 57 mm JS "Nahpatronen" cartridges for suppressed Mauser

Model 98 k rifles with long (35.4 mm) and heavy (12.75 grams) boat-tail bullets since 1942

until 1945. But those rifles had steep and uniform 240 mm rifling twist.

"Nahpatronen" were issued for German snipers only. They had selected Mauser

rifles with uniform bore and chamber dimensions in general.

Your mental calculation was incorrect: Despite of bullet's velocity it is rotating one

revolution when moving 304.8 millimeters (12 inches or one foot) in the bore and after

leaving the muzzle. At 140 mm distance from the muzzle is bullet made ca. 0.46 (less than

half) revolution. If inherent instability of a bullet is caused by excessive bullet length

(= too "slow" rifling rate, compared with bullet length), precession or

"yaw" of bullet starts not until it has advanced several meters away from the

muzzle or suppressor's end cap. Too low rotational rate is simply unable to overcome air

resistance's tendency to turn the bullet point upwards (or sometimes point-end downwards).

At a distance of 140 mm from muzzle, there is not yet air resistance ahead of bullet's

point, but a stream of powder gasses behind the bullet's base rushing past the bullet. In

the suppressor this is known as "gas blow-by". Another gas stream, known as

"precursor wave" has already blown the air (or powder gasses of previous shot)

away from suppressor. Bullet meet not yet air resistance and the yaw starts not yet. BUT

if the bullet's base is asymmetric, the powder gas stream is able to start yaw of bullet

soon after it's emergence from muzzle. Very small asymmetry shall cause a large precession

if the bullet's point is long and cylindrical "shank" of it is short. Center of

"Spitzer" bullet's gravity is close to the base.

Designer of Spitzer bullet, German Arthur Gleinich, was terrified when

he saw "spark photograps" of his bullets flying at distance ca. 50 centimeters

from a rifle muzzle. Longitudinal axis of some bullets was turn as much as 45 degrees of

angle away from the line of trajectory. But the center of bullet's gravity advanced along

with the trajectory and rotational stability was able to stop the precession after a short

flight. At 10 meters distance the bullet holes on target were no more oval or like

keyholes and accuracy of bullets was acceptable. If the air resistance only starts yaw of

a bullet, it's stability degrades slowly. If the bullet's base is faulty, the muzzle blast

starts precession very soon: The bullet may damage your suppressor despite of it's

shortness (140 mm) and sufficiently large bullet passages of baffles and end-cap. It is,

however, very frustrating experience to shoot excessively long and so unstable bullets.

One reason why I always recommend use of quick-burning powders for handloading of rifle

cartridges is inherently reduced volume of "muzzle blast", i.e. powder gasses,

and rather low pressure of the muzzle blast. (Less powder means: Less gasses). As a

perfectionist, with almost 20 years of experience with purposely and

"scientifically" designed subsonic handloads, I love "the golden

silence" of subsonic cartridges, shot with or without a suppressor.

Finnish-made commercially available suppressors are

designed to stand blasts of full-power rifle cartridges since early SuoMet

suppressor in 1980. Current BR-Tuote Reflex Suppressors are

made even for the long-range sniper rifles with caliber 12.7 x

99 mm Browning MG shooting full-power ammo. Many times I've shot Russian Maxim

and Degtaryev DP-27 machine guns with Reflex Suppressor

mounted, as well as German MG-34, using full-power factory loaded cartridges, of

course. Some careless (or EXCESSIVELY careful) handloaders are, however, wrecked Reflex

Suppressors by use of too slow-burning powders in their pet loads:

Finnish-made commercially available suppressors are

designed to stand blasts of full-power rifle cartridges since early SuoMet

suppressor in 1980. Current BR-Tuote Reflex Suppressors are

made even for the long-range sniper rifles with caliber 12.7 x

99 mm Browning MG shooting full-power ammo. Many times I've shot Russian Maxim

and Degtaryev DP-27 machine guns with Reflex Suppressor

mounted, as well as German MG-34, using full-power factory loaded cartridges, of

course. Some careless (or EXCESSIVELY careful) handloaders are, however, wrecked Reflex

Suppressors by use of too slow-burning powders in their pet loads:

According to Broemel QuickLOAD ballistic computer program 90 % of powder may burn in the

rifle barrel but 10 % burns inside the suppressor. Muzzle pressure may be much more than

700 atmospheres; i.e. as high as the CHAMBER pressure of modern shotgun. Suppressor

variation designed for 7.62 x 39 mm is also too small for .308 Winchester rifle, unless

subsonic or other "economy loads" are used ONLY! For shooting with full-power

loads the suppressor must be full-sized model with eight baffles.

Because loading data of these handloads is found from the loading manuals or handbooks it

is "Official Data", and it is impossible to prevent handloaders from assembly of

those horrible ear-splitting "boomers". In Finland is therefore designed another

class of suppressors by a firm Ase-Utra, < ase.utra@co.inet.fi >, Joensuu, Finland,

especially for shooting with full-power handloads or factory-loads; including .30 caliber

Magnum rifles. This AU suppressor is all-steel construction like Reflex Suppressors (also made by Ase-Utra). Baffles are

machined from steel bar-stock. Design of them is rather complicated. Patent is applied,

but not yet granted. Design is a real innovative novelty!

I know that most Finnish suppressor users are shooting full-power rifle cartridges

(factory-loads or handloads). Suppressor is usually acquired for prevention of excessive

shooting noise and loss of hearing, but also for dampening of recoil. Finnish suppressors

are able to eliminate the muzzle blast of usual rifles (example given .308 Winchester) so

that the supersonic crack is a dominant "shooting

signature". It is not deafening, but it is irritant! Most handloaders of subsonic

cartridges have not a suppressor at all. They cannot acquire it. Or they do not NEED it.

When the supersonic crack or flight noise is absent, the muzzle blast is also so low that

it is neither deafening nor irritant. Loading data for these "SWOS" loads (= Silent

WithOut Suppressor) is developed by us for riflemen in those countries where

suppressors are illegal to possess or they are very expensive devices, because of their

limited production and costly taxes or licence charges.

A friendly suggestion: Learn and start handloading! There shall presumably become no

successful .308 Winchester factory-loaded subsonic cartridges to be available "over

the counter" anywhere. Factory-loads shall become sold "For Official Use

Only!" But even the teen-ager lads are able to handload them, especially in Finland.

0212 MM; PT

More >>

<< New Q&A More Q&A,

part 9 >> Part 8 >> Part 7 >> Part 6 >>

Part 5 >> Part 4

>> Part 2 >> Part

1 >> Gunwriters guns.connect.fi Link page